Coatings 360

Harland’s Coatings 360 approach delivers tailored solutions to meet all your specific coating needs and goals.

Select an item on the graphic to learn more.

Everything you need for a successful hydrophilic coating program:

- Coating Solutions

- Method Development

- Coating Services

- Coating Equipment

- Testing Equipment

- Testing Services

- Surface Preparation

- Support & Maintenance

Method Development

Streamline your operations and ensure optimal coating performance.

The methods used to apply a coating is as critical as the coating solution itself. Harland's method development team helps to streamline your operations, validate coatings for production and ensure coating effectiveness throughout formulation and manufacture.

Surface Preparation

Dislodge and remove microscopic particles trapped near the device surface.

Surface contamination is the leading reason medical device coatings fail to adhere to catheters or other device surfaces. Harland’s line of surface preparation solutions is specially designed to remove potential contaminates from your medical device surface.

Coating Equipment

Automated coating machines to maximize your in-house coating.

Harland's line of coating equipment includes production scale coaters for applying and curing medical device coatings. Our versatile, high-throughput systems allow manufacturers to control production in-house.

Coating Services

Production-level contract coating services to help you achieve your objectives.

Harland is a reliable, dependable, economical manufacturing services partner. Our comprehensive coating capabilities undergo regular testing and reporting in accordance with ISO 13485 standards.

Coating Solutions

Tailored coating solutions formulated to reach your objectives.

Harland's line of coating solutions includes lubricious hydrophilic coatings, antimicrobial coatings, primers, and diluents. Our royalty-free formulations ensure manufacturers reach their performance, cost, and production goals.

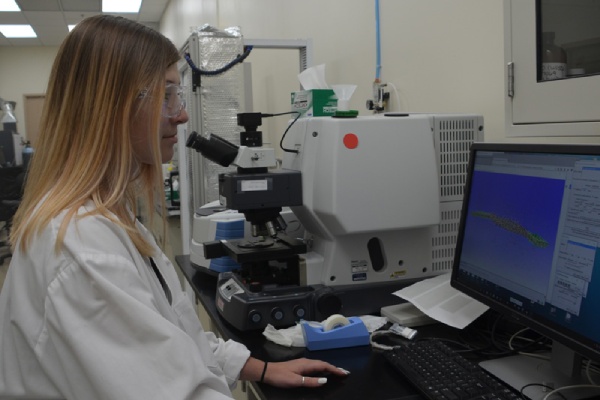

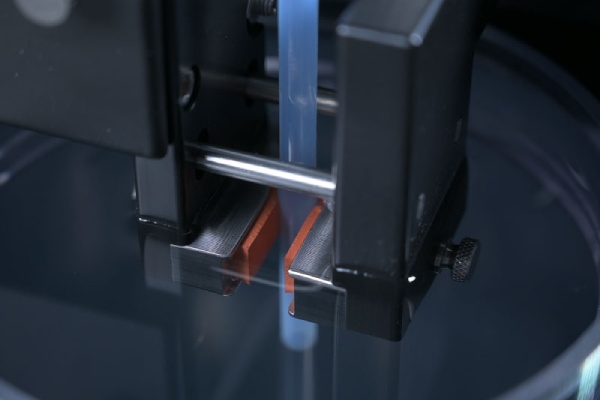

Testing Equipment

Tools to confirm coating efficacy, integrity and compliance in-house.

Harland's compact, versatile coating test systems are specifically designed to measure the lubricity, durability, and thickness of coating for catheters, guide wires, and other interventional devices.

Testing Services

Detect and correct any coating challenges.

Measure the performance of your device coating program by utilizing the full portfolio of testing services Harland offers. Our experience in measuring coating performance and our expertise in designing coating testing equipment makes Harland the ideal partner.

Support & Maintenance

Highly trained assistance over the entire device lifecycle.

Harland's support & maintenance includes access to medical device coating experts to help manufacturers solve coating-related problems. Maintenance is handled by full time OEM-trained technicians.