FTS7000™

Friction Testing System

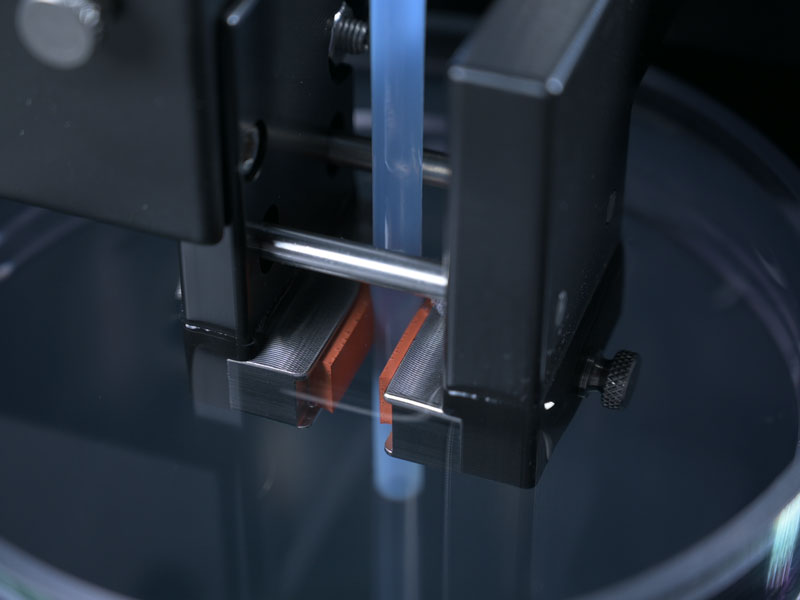

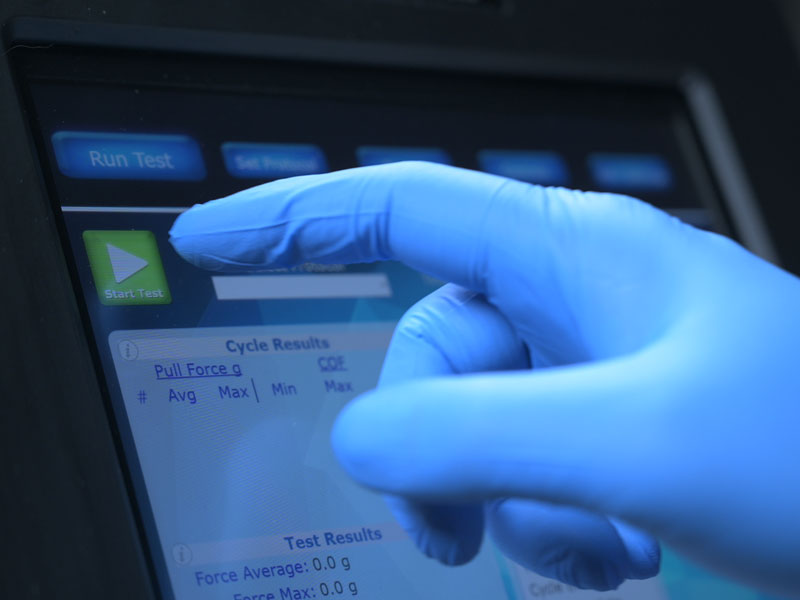

Harland Medical’s FTS7000 Friction Tester is a compact, versatile instrument specifically designed to help you measure the lubricity and durability of coatings for catheters, guide wires, introducers and other medical devices. The FTS7000 measures both surface friction and coating durability by drawing a test sample between two silicone rubber pads clamped at a programmable force, and then recording the pull resistance. The ease and accuracy of testing it provides makes it an ideal measurement tool for coating development, quality control and competitive product testing.