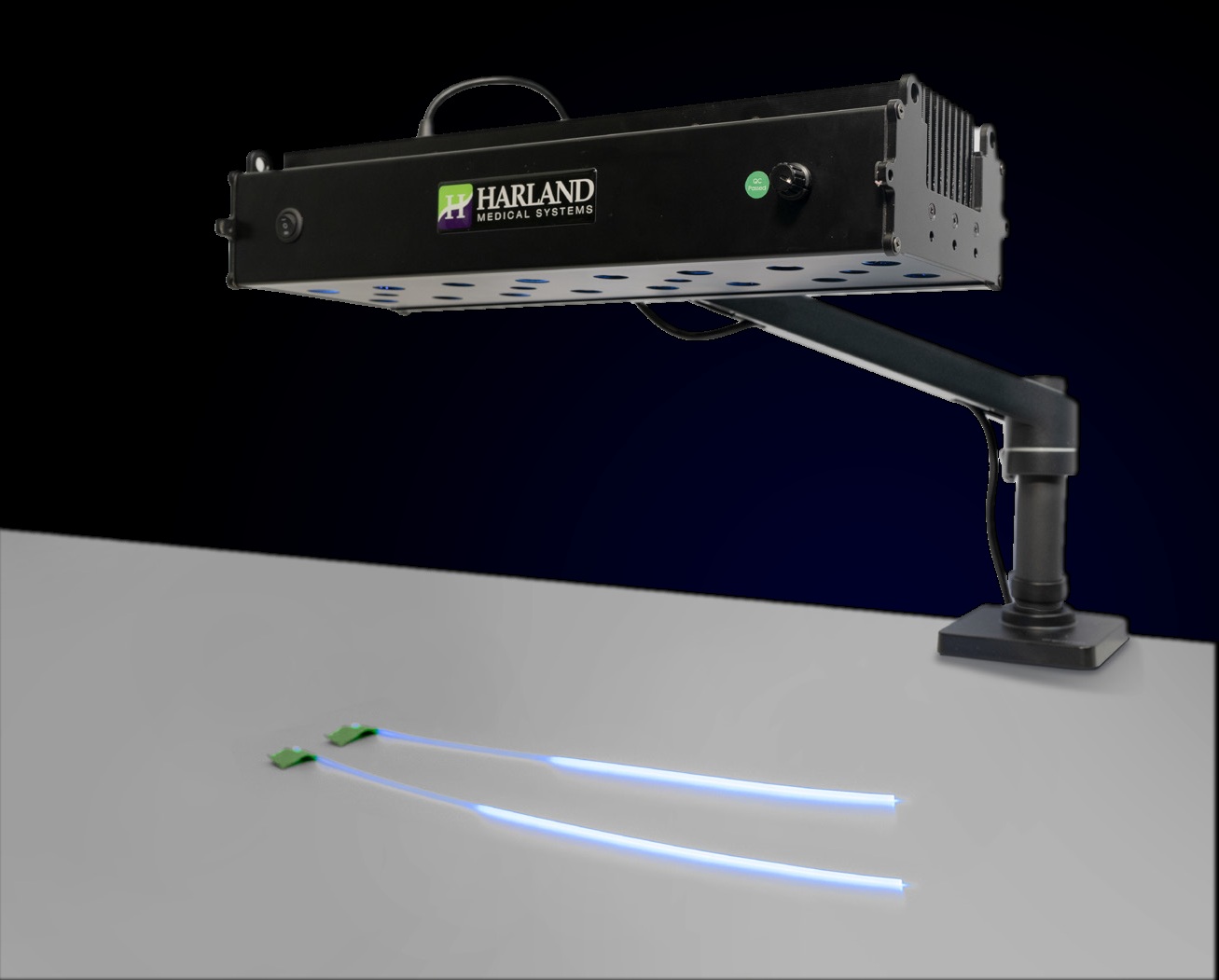

Lubricent® BrightView™

Fluorescing Hydrophilic Coatings

BrightView coating formulations enable cured coatings on devices to be easily visible under 365 nm long wavelength “blacklight” UV light.

The UV blacklight causes the cured coating to fluoresce visible light, making the coating easily visible without special instrumentation or destructive testing.