GWX

Specialty Automated Coating System

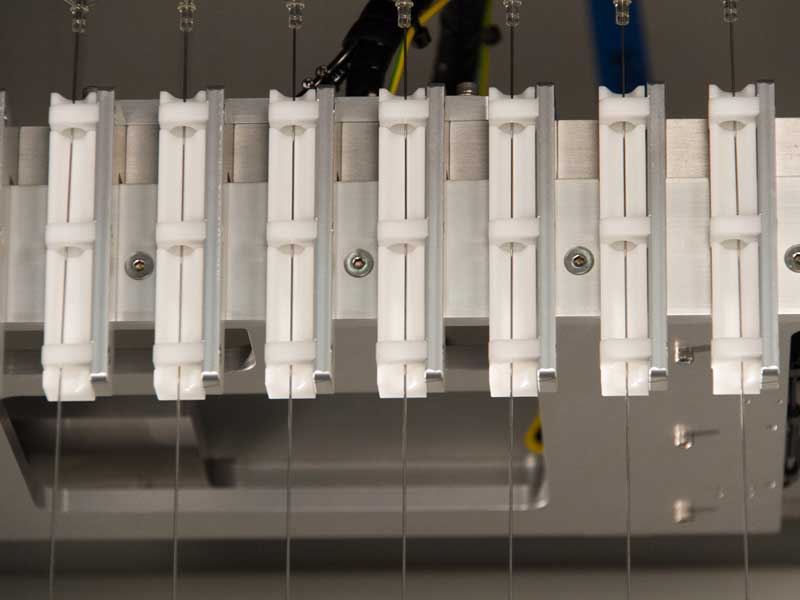

The GWX coating system is specially designed for long-length devices with relatively low column strength, such as guide wires or small diameter catheters. These characteristics can make these products particularly difficult to dip coat with traditional methods. GWX coaters integrate an innovative dip-coating process with UV cure, heat cure, or both in a single compact unit. Highly automated and hands-free, the system allows 12 devices to be loaded at once via a removable cassette. Modular construction allows you to select the predesigned feature packages and automation level required for your application without the long lead times and high costs associated with custom designed equipment.