Testing Services

Comprehensive Medical Device Testing Services

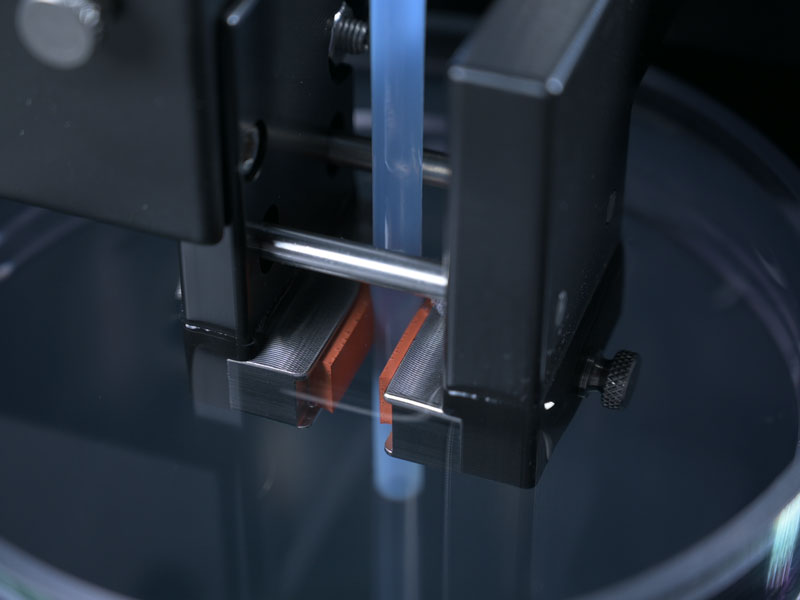

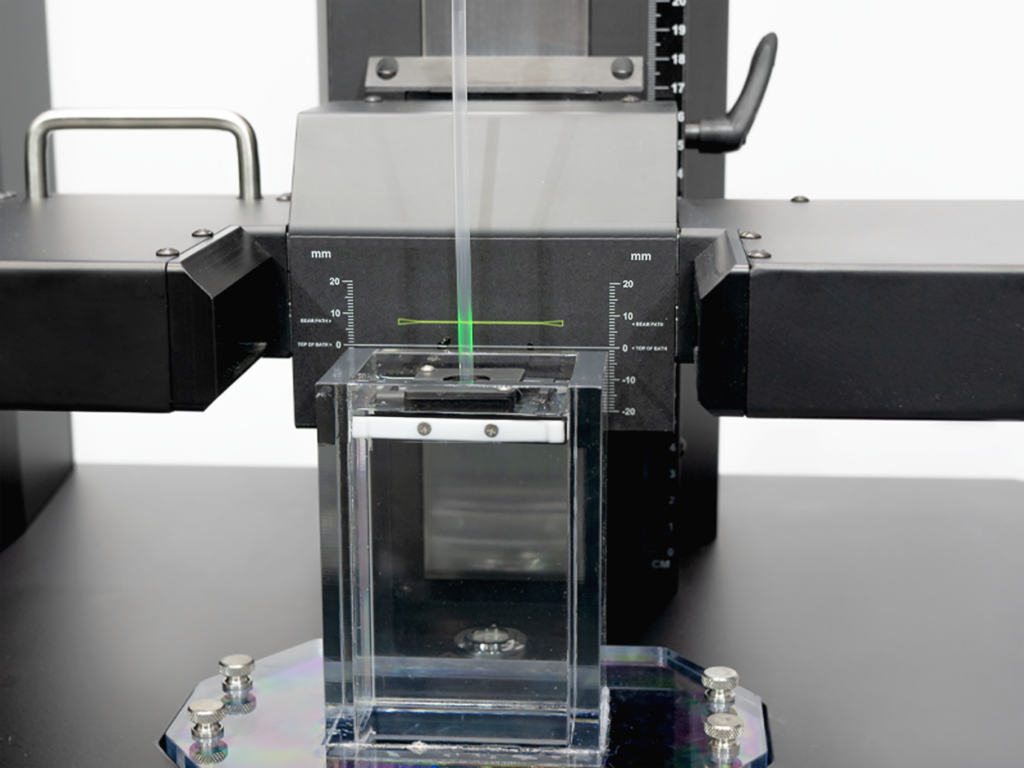

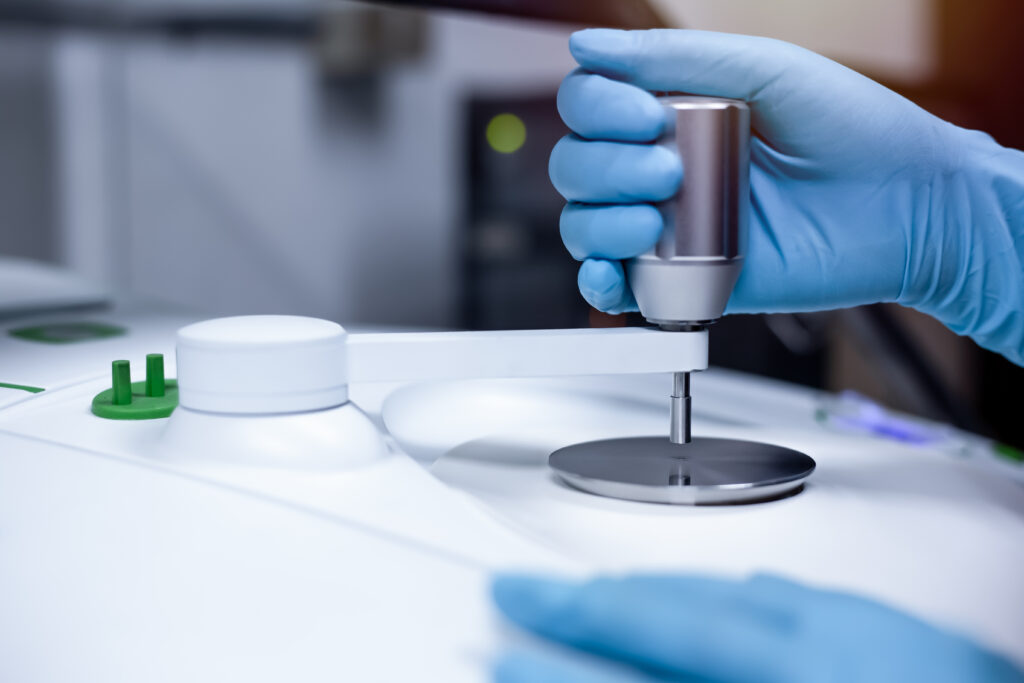

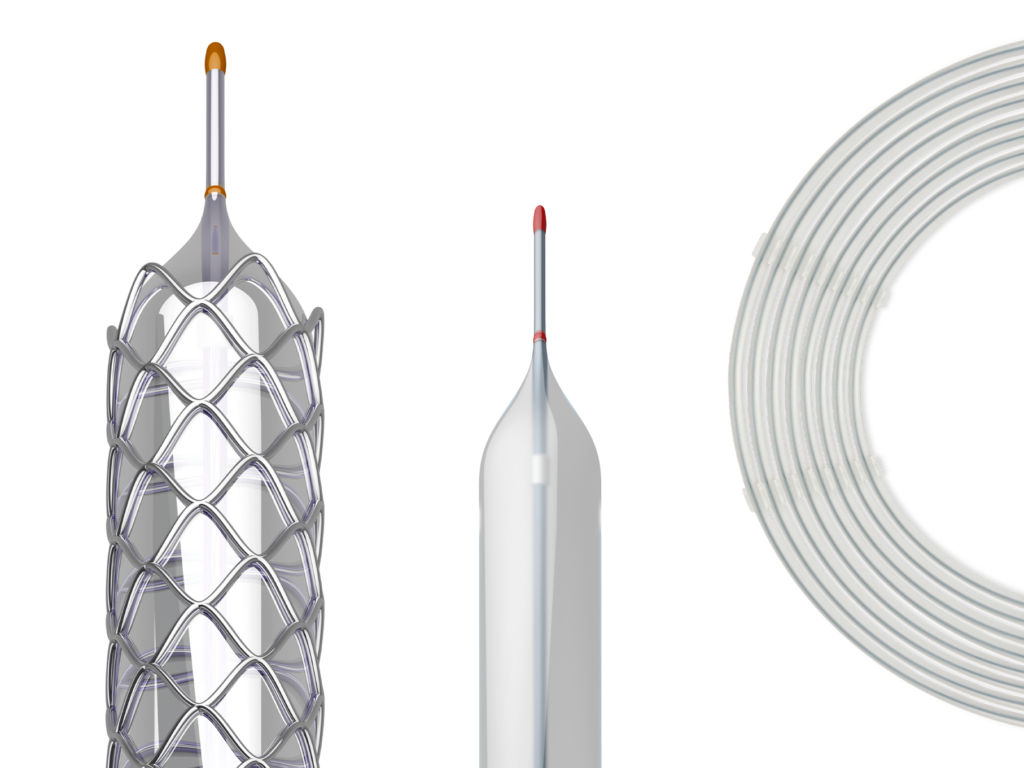

Measure the performance of your medical device coating program by utilizing the full portfolio of testing services Harland offers. Our experience in measuring coating performance and our expertise in designing coating testing equipment makes Harland the ideal partner for your coating testing needs. A quick turnaround means you can rely on Harland testing to keep your coating program on schedule.

Harland’s testing services laboratory is ISO17025 accredited.